-

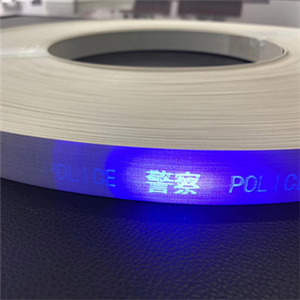

Anti counterfeiting edge banding strip

The Liyouli anti-counterfeiting edge banding has the following characteristics: 1. Strong anti-counterfeiting capability 2. Beautiful and durable 3. Easy to identify 4. Widely applicable 5. Good anti stripping performance

Anti counterfeiting edge banding strip PVC Anti counterfeiting edge banding strip ABS Anti counterfeiting edge banding stripSend Email Details -

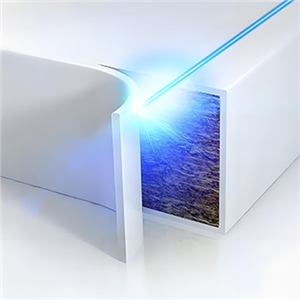

Laser edge banding

Material and Construction • Substrate: Common materials include ABS resin, PP, etc. The Huali Laser Edge banding 2.0 is mainly made of ABS resin as the substrate, which has good performance. Functional layer: also known as "laser coating", located on the back of the edge banding strip, with a thickness usually ranging from 0.15-0.2mm, composed of high melting point polymers, laser photoactive activation substances, etc. It is inert at room temperature and will be instantly activated by laser irradiation.

Send Email Details -

U-shaped card strip/self-adhesive strip

Advantages of U-shaped card strips 1. Easy installation: The design of the U-shaped card strip makes the installation process relatively easy. Usually, it is only necessary to align the card strip with the object or part that needs to be fixed, and then press it firmly or use simple tools to tighten it, without the need for complex tools or professional skills, greatly saving installation time and labor costs. For example, when installing small pipelines or cables, construction personnel can quickly clamp the U-shaped clamp onto the pipeline to complete the fixation. 2. Fixed firmly: The U-shaped structure can provide a large clamping force, firmly holding the fixed object to ensure that it will not easily loosen or shift during use. This feature makes it suitable for scenarios that require high fixed strength, such as fixing oil pipes, wire harnesses, and other components in the engine compartment of a car. It can withstand vibrations during vehicle operation and maintain stable component positions. 3. Good compatibility: The U-shaped card strip has various specifications and can adapt to the fixed needs of objects of different sizes and shapes. Whether it is circular, square or other shaped pipes and wires, suitable U-shaped clamps can be found for fixing. For example, in building decoration, it can be used to fix ventilation ducts of different diameters. 4. Reusable: U-shaped card strips are generally made of high-strength and durable materials, such as metal or high-strength plastic. When used correctly, it has a long service life and is relatively easy to disassemble. If it is not damaged after disassembly, it can be reused in other fixed scenarios, reducing the cost of use. Advantages of self-adhesive strips 1. Easy to operate: When using self-adhesive strips, simply peel off the release paper, stick the adhesive side to the desired position, and then press firmly without the need for additional glue, nails, or other fixing tools. The operation is simple, and even non professionals can easily complete the pasting work, improving work efficiency. For example, in home decoration, users can apply self-adhesive strips to the edges of furniture, walls, and other areas for decoration or protection. 2. Flexible application: Self adhesive strips can be attached to surfaces of various materials, such as wood, metal, plastic, glass, ceramics, etc., with a wide range of applications. Whether it is indoor decoration, handmade production, or temporary fixation and labeling in industrial production, it can all play a role. For example, in the production of electronic products, it is used to paste small labels, component cushioning pads, etc. 3. Beautiful and traceless: The self-adhesive strip has a smooth surface after pasting, without leaving holes or protrusions like nails, screws, or other fixing methods, which can maintain the integrity and aesthetics of the surface of the pasted object. In some places with high requirements for appearance, such as hotels and shopping malls, using self-adhesive strips to fix decorations, signs, etc. can achieve functionality without affecting overall aesthetics. 4. Removability: Some high-quality self-adhesive strips have the characteristic of being removable. When they need to be removed, they will not cause damage to the surface being pasted, nor will they leave too many adhesive marks. For some temporary pasting needs, such as pasting promotional posters, decorations, etc. in exhibition layout, self-adhesive strips and related items can be easily removed after the exhibition without damaging the original decoration of the venue.

Send Email Details -

Natural/dyed wood veneer edge banding

Natural/dyed wood veneer edge banding is a commonly used material in the field of home decoration. It is made by cutting natural wood into thin slices or dyeing it, and has the following advantages: Advantages of natural wood veneer edge banding 1. Natural beauty: Retain the texture, color, and texture of natural wood, with each piece of veneer having a unique texture that adds natural and authentic beauty to furniture, creating a warm and elegant home atmosphere. For example, walnut veneer edge banding has delicate texture, warm color, and high-end decorative effect. 2. Environmental protection and health: Using natural wood as raw material, with minimal addition of harmful chemicals, it meets people's pursuit of an environmentally friendly lifestyle. After simple processing, the natural properties of wood are preserved, which can reduce indoor environmental pollution and ensure the health of users. 3. Material stability: Wood itself has a certain strength and toughness. After being made into edge banding strips, it can effectively protect the edges of furniture boards, prevent them from being damaged due to collision and friction, reduce the risk of board moisture deformation, and extend the service life of furniture. 4. Strong repairability: If there are slight scratches or damages on the edge banding during use, simple repair methods such as polishing and repainting can be used to restore its appearance, and the overall aesthetics are basically not affected after repair. Advantages of dyeing wood veneer edge banding 1. Rich colors: Dyeing treatment is carried out on the basis of natural wood veneer, breaking through the limitations of natural wood color. Various colors can be blended according to design needs to meet different decoration styles and personalized needs. In modern minimalist style decoration, bright and solid colored dyed wood veneer edge banding can be chosen to create a fashionable atmosphere. 2. Highlight texture: The dyeing process can enhance the visual effect of the original texture of the wood, making the texture clearer and more vivid, emphasizing and beautifying the wood texture, and enhancing the artistic sense and uniqueness of decoration. 3. Coordinated matching: It can better match with other materials or colors on the surface of furniture, achieving a unified and coordinated overall spatial color tone. For example, pairing with artificial boards of specific colors to create furniture products with a unified style. 4. Preserve natural characteristics: Inherit the natural texture, environmental friendliness, material stability, and repairability of natural wood veneer, while giving the product more color choices, combining beauty and practicality.

Send Email Details -

EVA environmentally friendly hot melt adhesive

Shape: Round grain Color: Natural, White, Coffee Available Glue application temperature ℃: 180-210 ° C Melting viscosity: 75000CPS@200 °C Packaging: 25kg/snake skin bag Application materials: melamine veneer, PVC, MDF, ABS, Solid wood strips

EVA environmentally friendly hot melt adhesive EVA low-temperature hot melt adhesive Furniture edge banding adhesiveSend Email Details