-

Yak edge dual color edge banding strip

Acrylic edge banding is precision processed from acrylic resin and is a type of edge banding product with good transparency, weather resistance, impact resistance, and super wear resistance.

Yak edge dual color edge banding strip Yak edge solid color edge banding strip Yak edge wood grain edge banding stripSend Email Details -

Dining Table And Chair Cabinet Edge Strips

The following is an introduction to the highlights of edge banding for dining tables, chairs, and cabinets: Material Highlights PVC edge banding: Widely used, it has the characteristics of smooth surface, no bubbles, no stretch marks, moderate glossiness, and strong wear resistance. And the price is affordable, with rich colors and patterns, which can meet the design needs of different styles ABS edge banding: It is one of the internationally advanced materials, environmentally friendly, sustainable, and recyclable. It has the advantages of wear resistance, corrosion resistance, aging resistance, fire resistance, moisture resistance, etc. It has good dimensional stability, strong impact resistance, and good glossiness, and is often used in high-end panel furniture Aluminum alloy edge banding: The metal material gives the product a modern and perfect texture. It will not crack, is not easily deformed, has good scratch resistance, corrosion resistance, and weather resistance, has a long service life, good flexibility, is more environmentally friendly, and can protect edges and corners from collision and damage Feature Highlights • Protection function: It can seal the cross-section of the board to prevent damage from adverse factors such as moisture in the environment, prevent the board from getting damp and deforming, and also prevent formaldehyde volatilization inside the board. Strengthening the board makes dining tables, chairs, and cabinets more durable and environmentally friendly Antibacterial and anti mold function: Some edge banding strips use nano photocatalyst technology to inhibit and decompose bacterial proteins, achieving sterilization, air purification, deodorization, anti mold and other purposes, making the home environment healthier • Anti fingerprint and anti stain function: such as a seamless edge sealing strip that leaves no marks on the skin, does not touch the hands, has strong anti stain ability, can easily remove dirt with a wipe, and can maintain the cleanliness of the edge sealing strip surface Appearance highlights Highly decorative: It can create a clear and colorful overall effect on furniture, enhancing the aesthetics and quality of dining tables, chairs, and cabinets. Wood grain edge banding can present a realistic wood grain effect, while marble grain edge banding can bring the texture of stone • Rich in design: The irregular edge banding has different shapes such as arc and wave, which can meet different usage scenarios and design needs, making panel furniture design more user-friendly Good color and glossiness: LED ink is used to seal the edges with realistic and beautiful colors, realistic and clear textures, and no solvents, volatiles, or harmful substance residues, making it more environmentally friendly

Send Email Details -

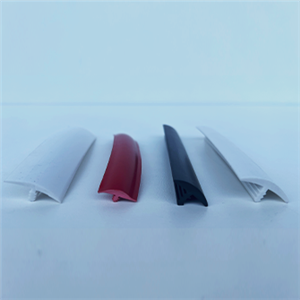

Office Countertop PVC Two Color Flat Edge Strips

The PVC dual color flat edge banding for office countertops has the following characteristics: Strong decorative appearance • Rich colors: Two different colors can be combined and matched, such as the common warm white with black, red, green, black and white 4-line, etc., to meet the color needs of different office environments and styles • Realistic effect: The surface has patterns such as wood grain, marble, and cloth, and the gloss is soft, with a sense of realism and three dimensionality of materials such as wood and stone, enhancing the grade of the office countertop Superior material performance • Stable quality: Smooth surface, no bubbles, no stretch marks, uniform thickness, consistent width, reasonable hardness, high elasticity, after trimming, the color of the edge sealing side is close to the surface color, without whitening, and the overall color of the furniture product is coordinated • Good durability: It has good wear resistance, chemical resistance, and corrosion resistance, can maintain the edge sealing effect for a long time, and is not easily damaged by friction, contact with chemical substances, etc. in daily use • Good environmental friendliness: The production uses environmentally friendly materials to ensure that the edge banding meets relevant environmental standards, reducing the harm to the office environment and human health Strong processing adaptability High plasticity: PVC material has good plasticity and can be bent, stretched and processed by heating or pressure, which can adapt to the edge sealing needs of office countertops with different shapes and curvatures The dual color countertop comes in various sizes: thickness generally ranges from 1.2 to 4mm, width from 28mm to 100mm, and can be selected and customized according to the thickness, width, and other dimensions of the office countertop Easy and fast installation Good adhesive strength: The adhesive layer on the back is evenly distributed and firmly adhered. When installing, simply align the edge banding with the edge of the office desk and apply appropriate pressure to firmly adhere, without the need for complex installation tools and processes Easy to trim: After the edge banding is done, tools such as knives can be used to trim it tightly to the edge of the office desk, achieving a beautiful and seamless edge banding effect High cost-effectiveness • Affordable price: Compared to ABS and other materials for edge banding, PVC two-color flat edge banding is more economical in price, which can reduce the production cost of office furniture while achieving better edge banding and decorative effects Low maintenance cost: Its good stain resistance and ease of cleaning make the office countertop only need to be wiped with a damp cloth to maintain cleanliness and tidiness in daily use, without special maintenance and upkeep, reducing the cost of later use

Send Email Details -

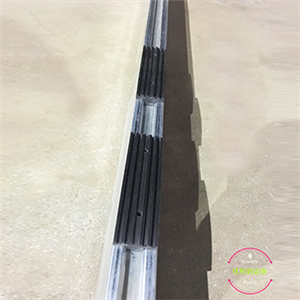

PVC ABS Environmentally Friendly Laser Edge Banding Strip

PVC/ABS laser environmentally friendly edge banding mainly includes the following aspects: In terms of appearance Seamless effect: Laser edge banding technology enables seamless bonding between the edge banding strip and the board, resulting in a more beautiful and natural appearance. Especially for light colored boards such as white and transparent boards such as acrylic, it can present a nearly perfect edge banding effect, improving the overall quality and grade of furniture. Rich colors: PVC/ABS edge banding can be printed with ink and other processes to present a variety of colors and textures, such as wood grain, stone grain, cloth grain, etc., to meet different furniture styles and personalized needs. Performance aspect High bonding strength: After laser activation of the functional layer of the edge banding strip, it is bonded to the board particles' rivets' with high bonding strength, greatly improving the durability of the bonding peel strength and enhancing the durability of the furniture. • Good heat resistance: ABS edge banding itself has high heat resistance and is not easily deformed or melted; Laser edge sealing technology further enhances its heat resistance, allowing furniture to adapt to different temperature environments and extend its service life. Strong light resistance: It has good light resistance and is not easily faded or discolored under long-term light exposure, ensuring that furniture always maintains a good appearance during use.. Waterproof and moisture-proof: effectively prevent moisture from entering the board, protect the board from moisture and deformation, improve the moisture-proof performance of furniture, suitable for various humid environments such as kitchens, bathrooms, etc Processing aspect • Precise and efficient: The laser edge banding equipment can automatically adjust parameters according to the type of edge banding tape, with precise and convenient operation, improving processing efficiency and stability of edge banding quality, and reducing manual operation errors. Reduce pollution: It eliminates processes such as glue coating and anti sticking agent spraying, avoiding the volatilization and pollution of glue. At the same time, there is no need to clean components such as glue pots and scrapers, reducing environmental pollution and making it more environmentally friendly and energy-saving. • Cost reduction: By eliminating the need for a large amount of hot melt adhesive and reducing equipment maintenance and cleaning costs caused by adhesive contamination, processing and labor costs have been lowered. Environmental and health aspects • No glue evaporation: The hot melt adhesive used in traditional edge sealing processes may release harmful substances, while laser edge sealing technology does not require glue, avoiding air pollution caused by glue evaporation and creating a healthier home environment for users. Material Environmental Protection: PVC/ABS materials themselves are relatively environmentally friendly, with minimal impact on the environment and human health during production and use, meeting the requirements of modern eco-friendly homes.

PVC environmentally friendly edge banding strip PVC laser edge banding strip ABS environmentally friendly edge banding stripSend Email Details -

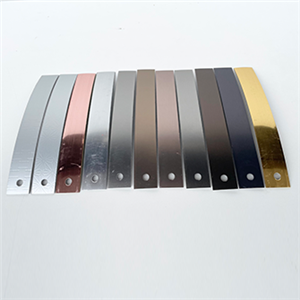

Metal Brushed PVC Stainless Steel Edge Banding

Introduction to the characteristics and uses of PVC metal wire drawing edge banding: features 1. Appearance presentation • Metallic texture: It has a realistic metal drawing effect, and through special processes, its surface presents a texture similar to that of finely drawn metal. It is visually textured and looks high-end and fashionable, adding a unique modern industrial or luxury style charm to furniture. • Rich colors: Based on the metal brushed texture, there are various colors available, including silver, gold, black, gun gray, etc. The corresponding colors can be selected according to different design needs and matching styles to complement various types of furniture in color. Moderate glossiness: The surface luster is soft and not too dazzling or exaggerated, while also highlighting the unique luster of the metal material, creating a low-key yet tasteful appearance effect. 2. Material characteristics • Good flexibility: As a PVC material, it has a certain degree of flexibility and can be easily bent along the edges of the board during installation, adapting to different shapes of edges. For example, it can fit the contours of curved furniture without easily breaking, making it easy to process and use. • Dimensional stability: The thickness and width dimensions are relatively precise and stable, and are not easily deformed or stretched under different environmental conditions, ensuring the durability and stability of the edge sealing effect, and enabling the edge sealing strip to maintain a good fitting state for a long time. Strong durability: It has good wear resistance and corrosion resistance. Even with frequent contact and friction in daily use, it is not easy to have scratches, discoloration and other problems. At the same time, it also has a certain resistance to some common chemicals, water vapor, etc., and can adapt to relatively complex use environments such as kitchens and bathrooms. 3. Processing performance Easy to process: easy to cut, using ordinary cutting tools can cut according to the required length, and after cutting, the edges are relatively flat without roughness, cracking, or other phenomena; In addition, during the bonding and installation with the board, it can be smoothly completed through conventional edge sealing processes such as heating and gluing, with low operational difficulty, suitable for large-scale production processing and on-site installation and use. Wide adaptability: It can be used in combination with various types of boards, such as particleboard, medium density fiberboard, multi-layer board, etc. Regardless of the material and thickness of the board, as long as the appropriate specification of PVC metal wire drawing edge banding strip is selected, a good edge banding effect can be achieved, and the versatility is strong. 4. Environmental attributes: High quality PVC metal wire drawing edge banding follows environmental standards in the production process and usually does not contain excessive harmful substances. For example, formaldehyde emissions can be controlled at a very low level, which meets the basic requirements of indoor decoration materials for environmental protection and has minimal health hazards to users. purpose 1. Furniture manufacturing Cabinet application: Used for edge sealing of doors and cabinets, making the overall style of cabinets more robust and fashionable, especially for modern minimalist or industrial style designed cabinets. Paired with this metal brushed edge sealing strip, it can enhance the quality and aesthetics of cabinets. At the same time, its wear-resistant and corrosion-resistant characteristics can also effectively deal with oil stains, water vapor and other situations in the kitchen. • Wardrobe use: Used on the edges of wardrobe doors, side panels, etc., it can add a unique modern feel to traditional wooden wardrobes, break monotony, and create a unique visual effect. The metal brushed appearance is also easy to match with different decoration styles, whether it is Nordic style, light luxury style, or modern mixed style, it can be integrated with it. • Furniture such as desks and dining tables: PVC metal brushed edge banding can also play a role in the edge treatment of furniture such as desks and dining tables, creating a delicate and personalized appearance. It can also use its durability to protect the edges of furniture and reduce collision damage during daily use. 2. Commercial display Showcase production: Used in shopping malls, exhibition halls, and other places to produce various types of display cabinets, such as jewelry display cabinets, electronic product display cabinets, clothing display cabinets, etc. Its metallic texture and beautiful brushed texture can attract customers' attention, better display products, and showcase the high quality of display cabinets, enhancing the level of exhibits and the image of the entire display area. Store decoration: Using it in the decoration of the store, such as the checkout counter, shelves, etc., helps to create a unified style, highlight the characteristics and professionalism of the store, leave a good visual impression on customers, and enhance the recognition and attractiveness of the store. 3. Interior decoration Door and window frames: As edge sealing materials for door and window frames, they can add metallic texture to doors and windows, making the overall interior decoration style more personalized. They form a sharp contrast with traditional wooden or plastic door and window frames, bringing novel and unique decorative effects. At the same time, they can also protect the edges and reduce wear and tear functionally. Kickboard: Used for making kickboards, it can not only enhance aesthetics and create unique visual highlights with its metal brushed appearance, but also has good wear and corrosion resistance to cope with daily mopping, bumps, and other situations, making it highly practical.

Send Email Details -

PVC Anti Slip Mats Iron Pallet Foot Pads

The tray anti slip foot pad has many advantages, including: In terms of anti-skid performance 1. Place items firmly Tray anti slip foot pads are usually made of materials with high friction, such as rubber, silicone, etc. When the tray is placed on a desktop, tabletop, or other load-bearing surface, a strong friction force can be formed between the foot pad and the contact surface, effectively preventing the tray from easily sliding due to accidental collisions, slight shaking, etc., ensuring that the items placed on the tray, whether it is tableware, glass products, documents, or various goods, can be stably placed on the tray, reducing the risk of items slipping and being damaged. 2. Adapt to multiple surfaces It can exert good anti slip effect on bearing surfaces of various materials and surface conditions. Whether it is a smooth marble tabletop, a wooden tabletop, or a textured tile surface, the anti slip foot pad can tightly fit and adjust its own state to adapt to different surface characteristics such as roughness and hardness, maximizing the stability of the tray and expanding its range of usage scenarios. In terms of protecting the bearing surface 1. Avoid scratching During frequent movement and placement of the tray, if there are no anti slip foot pads, the bottom edge of the tray is likely to scratch the load-bearing surface such as the desktop and tabletop. Over time, it is easy to leave unsightly scratches, affecting the aesthetics and integrity of the load-bearing surface. And the anti slip foot pad plays a role in buffering and isolation. Its soft material can prevent the tray from directly contacting the bearing surface and causing friction, protecting the bearing surface from scratches. Especially for some expensive wooden furniture, exquisite marble countertops, etc., this protective effect is very important. 2. Prevent wear and tear In addition to scratches, long-term use of trays may also cause wear and tear on the load-bearing surface, reducing its service life. Anti slip foot pads can effectively slow down the wear rate of the bearing surface by dispersing the pressure of the tray on the bearing surface, allowing the bearing surface to maintain a good condition for a long time and reducing the cost and trouble of replacing or repairing the bearing surface due to wear. Noise reduction aspect 1. Reduce placement noise In daily use, when placing a tray on a desktop, there is often a certain impact sound, especially in quiet environments such as offices, libraries, bedrooms, etc., which may cause interference. Anti slip foot pads can provide cushioning and absorb some of the energy generated by impact, significantly reducing the noise emitted when placing trays, creating a relatively quiet environment, and enhancing the user experience. 2. Reduce movement noise If it is necessary to move the tray without anti slip foot pads, the friction between the tray and the bearing surface can easily produce a harsh sound. During the movement of the tray with anti slip foot pads, the friction between the foot pads and the bearing surface is relatively soft, resulting in minimal noise and no annoying sounds, making the movement of the tray quieter and smoother. In terms of aesthetics and cleanliness 1. Improve the overall aesthetics of the tray Anti slip foot pads come in various colors, shapes, and designs to choose from. They can be matched with corresponding foot pads according to the material, style, and usage scenario of the tray, playing a decorative role and making the tray look more delicate, beautiful, and coordinated with the surrounding environment. For example, trays used to hold tableware in hotels and restaurants, paired with elegant silicone anti slip foot pads, can add a touch of style to the service. 2. Easy to clean and maintain Most non slip foot pads have a relatively smooth surface and are not easily contaminated with dirt. When cleaning daily, simply wipe them gently with a damp cloth to remove dust, stains, etc. And if the foot pad is dirty or aged, it is also relatively easy to replace, with low cost, and will not bring too much burden to the cleaning and maintenance work of the tray. Applicability and universality 1. Adapt to trays of different sizes Whether the tray is a large-sized industrial tray used for carrying heavy objects or a small and delicate service tray used for home life, suitable anti slip foot pads can be found to match it, and can be flexibly cut and installed according to the actual shape and size of the tray to ensure that the foot pads can fully cover the bottom of the tray

Send Email Details -

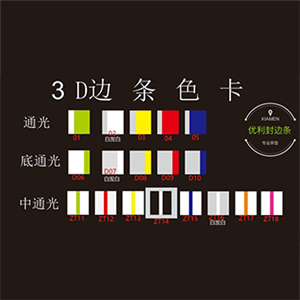

Color shaped edge banding

Colorful edge banding has the following characteristics and advantages: Highly decorative Rich colors: There are multiple colors to choose from, such as bright and lively bright colors, calm and atmospheric dark colors, etc., which can meet the needs of different consumers for furniture color matching and adapt to various decoration styles. • Diverse shapes: In addition to the common flat edge banding, there are also various styles such as 3D stereoscopic shapes and irregular shapes, such as edge banding with concave convex textures and patterned patterns, which can make furniture edges more three-dimensional and layered. Good protection performance • Wear and tear prevention: It can effectively protect the edges of furniture panels, reduce damage caused by collisions, friction, etc. during daily use, and extend the service life of furniture. Moisture proof and Waterproof: It can prevent moisture from entering the interior of the board, prevent the board from becoming damp, deformed, moldy, and rotten, especially suitable for furniture in damp environments such as kitchens and bathrooms. Environmental Protection and Health Material safety: High quality colored edge banding is made of environmentally friendly materials, such as PVC that meets national standards ABS、 Acrylic and other harmful substances have low release levels and are harmless to human health and the environment. • Odorless: Environmentally friendly edge banding strictly controls the use of additives in the production process, does not emit pungent odors, and creates a healthy and comfortable environment for home use. High durability Wear resistant and scratch resistant: It has good wear resistance and scratch resistance, is not prone to scratches, wear and tear, and can maintain the beauty and integrity of the edge banding for a long time. • Anti aging: Under normal use conditions, it is not easy to fade, discolor, embrittlement and other aging phenomena, and can maintain the original performance and appearance for a long time. Easy to process and install Easy cutting: It can be cut according to the size and shape of furniture, flexibly adapting to different edge sealing needs, and the operation is simple and convenient. • Easy installation: Usually installed using hot melt adhesive, back glue, and other methods. Simply stick the edge banding to the edge of the board without the need for complex tools and techniques, resulting in high installation efficiency. ...

Send Email Details -

Flat furniture edge banding

Flat furniture edge banding is used to wrap around the edges of furniture panels, enhancing aesthetics and protective performance. The following are its common features: 1. Diverse materials Wood: Made from natural wood materials such as birch, oak, etc., it can present a natural and authentic wood grain texture, which complements solid wood furniture and creates a warm and rustic atmosphere. PVC: Made of polyvinyl chloride material, with low cost and good flexibility, it can adapt to edge sealing of different shapes of boards, with rich colors and textures, and can imitate the appearance of various materials. ABS: Made of acrylonitrile butadiene styrene copolymer, it has good wear resistance, impact resistance, smooth surface, full color, and good trimming effect. It is commonly used in mid to high end furniture. • Acrylic: chemical name is polymethyl methacrylate, with high transparency, similar to glass texture, strong weather resistance, anti-aging, making furniture look high-end and fashionable. 2. Rich color and texture: It can simulate the colors and textures of various materials such as wood, stone, leather, etc., such as oak and marble patterns, to meet the design needs of different furniture styles, from classical to modern styles. 3. Good protection performance Wear resistant: Effectively protect the edges of the board, reduce damage caused by scratches and collisions during daily use, and extend the service life of furniture. Moisture proof and waterproof: It blocks external moisture from entering the board, preventing deformation, mold, decay and other problems caused by moisture, especially suitable for furniture in damp environments such as kitchens and bathrooms. 4. Convenient processing Convenient cutting: According to the size of the board, ordinary cutting tools can easily cut it to the appropriate length, and the operation is simple. Easy to stick: When sticking to the board, it can be firmly bonded with hot melt adhesive or other specialized glue under appropriate temperature and pressure, which is convenient for furniture production enterprises to improve production efficiency. 5. Environmental performance: With the increasing awareness of environmental protection, many edge banding strips are made of environmentally friendly materials that meet relevant environmental standards, such as meeting E1 or higher formaldehyde emission standards, providing consumers with healthy home products.

Send Email Details