-

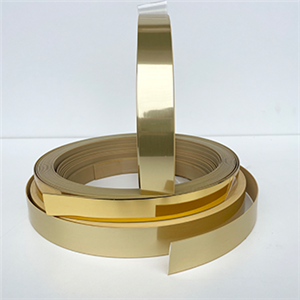

Gold Mirror Edge Banding

Characteristics of golden edge banding: Appearance characteristics • Unique visual effect: Gold exudes a luxurious and elegant temperament, instantly elevating the level of furniture or decorative objects, creating a luxurious and atmospheric atmosphere, making it particularly eye-catching among numerous edge banding strips, with strong decorative and visual appeal. • Color richness: Gold is not a single color tone, it covers a variety of different sub colors such as bright gold, brushed gold, rose gold, antique bronze gold, etc. Each color tone can also showcase unique style characteristics. For example, bright gold is more dazzling and suitable for creating a modern luxury style; Rose gold exudes a soft and romantic atmosphere, often used in some exquisite and elegant design scenes; Ancient copper and gold have a rustic and heavy charm, which meets the matching needs of retro style. Gloss performance: It usually has good glossiness and can reflect light, making it look shiny. Under different lighting conditions, whether it is natural light or lighting, the golden edge banding can become the visual focus, adding bright color elements to the overall space. Material characteristics • Material diversity: Golden edge banding can be made from various basic materials, including PVC ABS、 Metals (such as aluminum alloys), etc. PVC gold edge banding is affordable, flexible, easy to process, and has stable color and gloss retention; ABS gold edge banding has better performance, higher hardness, wear and scratch resistance, and strong dimensional stability; The aluminum alloy gold edge banding has a tough texture, excellent deformation resistance, corrosion resistance, and long service life, as well as a unique metallic texture. • Good stability: High quality golden edge banding is relatively stable in size, and will not easily change in width, thickness, or deformation due to environmental factors such as temperature and humidity, ensuring long-term good edge banding effect and appearance integrity, so that furniture or decoration after installation always presents a delicate state. Processing characteristics Easy to process and shape: Regardless of the material, most golden edge banding strips have good processing performance. For example, PVC and ABS gold edge banding can be adapted to different shapes of board edges through conventional operations such as cutting and hot bending. The cutting edge is flat during cutting, and it is not easy to break during hot bending, making it convenient for flexible processing in furniture production; Although the golden edge banding made of metal material has a relatively hard texture, it can also be bent, cut, etc. through professional processing equipment, and the processing accuracy is high, resulting in good finished product effects. • Installation convenience: Most gold edge banding strips come with a sticky adhesive layer on the back. When installing, simply align them with the area that needs to be sealed and press them firmly. The operation is simple, without the need for complex installation tools or complicated processes, which can effectively improve installation efficiency and save labor and time costs. Durable characteristics Wear resistant and scratch resistant: In daily use, gold edge banding needs to withstand various friction, scratches, and other situations. Good gold edge banding has a certain degree of wear resistance, and materials such as ABS and metal can effectively resist external damage to its surface, maintain the golden appearance and glossiness of the surface, reduce the occurrence of scratches, fading, and other phenomena, and extend its service life. Corrosion resistance: Especially the golden edge banding made of metal materials, as well as some high-quality plastic materials, have a certain tolerance to common chemicals such as cleaning agents, acidic and alkaline solutions in daily life, and will not be easily corroded, discolored or damaged, making them suitable for relatively complex use environments such as kitchens and bathrooms, ensuring their stable performance. Environmental characteristics Compliance with environmental standards: Our company strictly controls the release of harmful substances in accordance with relevant environmental standards for gold edge banding produced in a formal manner, regardless of the material used. For example, plastic materials can control the production of pollutants such as formaldehyde, while metal materials should avoid containing harmful heavy metals to ensure that they do not have adverse effects on human health and indoor environment during use.

Send Email Details -

PVC ABS Edge Banding Strip Factory

Details: Selected high-quality edge banding strips, crafted with precision technology, with delicate and smooth edge cutting, without any burrs, closely adhering to the board, effectively preventing dust, water vapor and other erosion, and long-lasting protection of home quality color and lustre: The edge banding has a rich and fashionable color selection, from classic matte black, elegant ivory white to atmospheric walnut wood color, all of which use environmentally friendly high color rendering coatings. The color is full and uniform, long-lasting and bright, easily matching various home styles Material placement: Highlight the main style: Place the exquisitely rendered image of the actual border strip in the center of the banner image, occupying a large space and allowing viewers to focus on the border strip itself at a glance.

Send Email Details -

Fireproof Board Sealing Edge Strip

The fireproof board edge banding has the following characteristics: Diverse materials Mainly PVC ABS、 Solid wood and other materials. PVC edge banding is cost-effective, comes in a variety of colors, and has good flexibility; ABS edge banding has better performance, high hardness, good glossiness, wear and scratch resistance; Solid wood edge banding has a natural texture and high grade, and can be paired with fireproof board to enhance overall aesthetics Good fire resistance performance It has a certain degree of fire prevention function and can prevent the spread of fire to a certain extent. When used in combination with fireproof boards, it can enhance the fire resistance of furniture or buildings and improve safety High color and appearance matching Rich in color, it can coordinate with the color of the fireproof board to achieve an overall beautiful effect, and the surface can be made into a texture similar to the fireproof board, such as wood grain, stone grain, etc., so that the edge banding and fireproof board are integrated without obvious boundaries Wear resistance Has good wear resistance, can withstand friction and collision in daily use, is not easily damaged by scratches, wear, etc., ensures the integrity and aesthetics of the edge sealing, and extends the service life Strong corrosion resistance It has good tolerance to some common chemicals, is not easily corroded or discolored, and can maintain stable performance under different environmental conditions. It is suitable for places such as kitchens and bathrooms that are humid or have chemical pollution risks Good processing performance The texture is soft and has a certain degree of toughness, easy to bend, cut, and install. It can be fixed on the edge of the fireproof board through hot pressing, pasting, and other methods. It can also be made into various shapes according to needs, such as inclined, semi-circular, duckbill, etc., to meet different design requirements Excellent environmental performance High quality fireproof board edge banding usually meets relevant environmental standards, has low formaldehyde emission, is harmless to human body and the environment, and is safe and reliable to use

Send Email Details -

Multi Flower Density Layer Board Sealing Strips

Multi layer board and density board edge banding have a wide and important range of applications. The following is a detailed introduction for you: Enhance aesthetics Unified appearance style: Multi layer boards and density boards are commonly used to make furniture, such as wardrobes, cabinets, desks, etc. Edge banding can modify the rough and unsightly edges of the board to present a neat and smooth appearance, and can match the color and texture of the board surface, creating a unified overall visual effect and enhancing the grade and quality of the furniture. • Achieving personalized design: Edge banding has a wide range of colors and patterns to choose from, such as wood grain, stone grain, solid color, etc. By selecting different edge banding, unique decorative elements can be added to furniture to meet various personalized design needs. For example, using simple solid color edge banding on modern minimalist style furniture, or matching realistic wood grain edge banding on retro style furniture to create an atmosphere. Enhance protection performance Moisture and Waterproof: Multi layer boards and density boards are prone to moisture deformation, mold and other problems when exposed to moisture, especially for furniture used in relatively humid environments such as kitchens, bathrooms, balconies, etc. Edge banding can seal the edges of the board, effectively blocking the intrusion of external moisture, protecting the internal structure of the board, and extending its service life. • Anti collision and wear: During daily use, the edges of furniture are prone to collision and scratching. Edge banding can act as a layer of "protective cover", reducing external impact forces and minimizing damage to the edges of the board with its good wear resistance, allowing furniture to maintain good integrity. Beneficial for environmental protection and health Reduce formaldehyde emissions: Multilayer boards and density boards may retain a certain amount of formaldehyde during the production process. Edge banding can seal the edges of the board, reducing the amount of formaldehyde emitted from the edges, thereby reducing indoor formaldehyde concentration to a certain extent and creating a healthier living and usage environment. Easy to process and install Simplify the processing flow: In the furniture manufacturing process, the installation of edge banding is relatively simple and convenient. It can be firmly attached to the edge of the board through edge banding machine hot pressing, adhesive bonding and other methods. Compared with the complex polishing, decoration and other processing methods of the board edge, using edge banding can greatly improve production efficiency and reduce processing costs. • Compatible with multiple shapes: Edge banding has good flexibility and plasticity, and can adapt to edges of different shapes of multi-layer boards and density boards. Whether it is straight edges or curved edges with a certain curvature, they can be well sealed, which makes them play an important role in making irregular furniture. Expand application scenarios Application in commercial places: In offices, shopping malls, hotels, and other commercial places, office furniture, display cabinets, partitions, etc. made of multi-layer boards and density boards combined with edge banding can meet the requirements of large-scale use and cost control, while ensuring aesthetics and durability, and enhancing the overall image of the space. Extension in the field of home decoration: In addition to common furniture, in home decoration, using them to make door frames, window frames, baseboards and other components, edge banding can also play a role in decoration, protection and coordination with the overall style, enriching the details of home decoration elements.

Send Email Details -

3D edge banding

Unique advantages of 3D edge banding 1. Realistic stereoscopic effect 2. Rich and diverse designs 3. Good durability 4. Environmental protection and health 5. Easy installation 6. Seamless fit

Send Email Details -

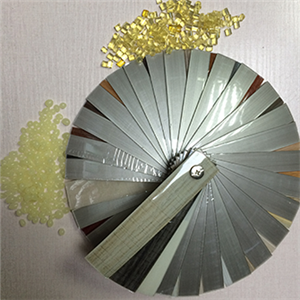

Textured metal brushed edge strip

Core composition and craftsmanship • Base material: Extruded from high-purity ABS resin, free of fillers such as calcium carbonate, with uniform overall coloring. The trimmed section maintains a consistent color, eliminating any whitening phenomenon • Surface craftsmanship: Through vacuum coating, transfer printing, or special coating techniques, combined with fine brushing treatment, a realistic metallic texture is presented (such as stainless steel, aluminum alloy, champagne gold, etc.). The surface is usually covered with a layer of UV wear-resistant coating to enhance durability Key features and advantages 1. High-end appearance: The metal brushed texture is delicate and uniform, with moderate glossiness, which can enhance the overall grade of furniture and is suitable for various design styles such as modern minimalist and industrial style 2. Excellent performance: ABS base material features high impact resistance, wear resistance, corrosion resistance, aging resistance, good dimensional stability, resistance to deformation and cracking, and a long service life 3. Convenient processing: Similar to ordinary ABS edge banding, it can be mechanically or manually sealed, and is compatible with various processes such as EVA, PUR, and laser edge sealing. The edges are smooth and translucent after trimming 4. Environmental safety: ABS resin additives are added in small amounts, are recyclable, meet environmental standards, release no harmful substances, and are suitable for indoor furniture 5. High cost-effectiveness: Compared to genuine metal edging strips, it is lighter in weight and lower in cost, and avoids the disadvantages of metal edging, such as being prone to scratching and difficult to process Typical application scenarios • Exposed edges of high-end custom furniture (cabinets, wardrobes, bookcases) • Decorative parts of commercial space display cabinets, cash registers, etc. that need to highlight the metallic texture • Furniture edges in wet environments such as kitchens and bathrooms are sealed, providing both moisture resistance and aesthetic appeal • Scenarios where both durability and aesthetics are required, such as office furniture and laboratory furniture Specification reference • Thickness: 0.4-3mm (commonly used 1-2mm) • Width: 12-80mm (customizable) • Color: rose gold, titanium brushed, stainless steel, bronze, champagne gold, gun gray and other metal colors

Textured metal brushed edge strip Textured metal aluminum brushed edge banding Hand-brushed metal edge stripSend Email Details -

Environmentally friendly acrylic edge banding strip

Acrylic edge banding stands out in furniture decoration with its unique performance and texture. The following are its main highlights: 1. High transparency and texture: Acrylic, also known as polymethyl methacrylate, has a high transparency like glass, which can create a crystal clear visual effect, enhance the overall grade of furniture, give furniture a fashionable and modern texture, and highlight its unique charm in various types of furniture. 2. Excellent weather resistance: It has good tolerance to ultraviolet rays in sunlight and is not prone to discoloration or aging under different climatic conditions. Whether it is a living room with sufficient sunlight for a long time or a bathroom with high humidity, it can maintain its original color and performance, and remain fresh over time. 3. Good impact resistance: Compared to ordinary glass, acrylic has higher toughness, strong impact resistance, and is not easily broken. Even if subjected to a certain degree of impact, it can avoid the safety hazard of glass breakage and improve the safety of furniture use. 4. Easy to process and shape: When heated, it has strong plasticity and can be easily processed into various shapes through processes such as hot bending and hot pressing, meeting different furniture design needs, achieving unique shapes and creative designs, and adding personalized elements to furniture. 5. Rich and long-lasting colors: Different colorants can be added to create a variety of colors with good color stability, and long-term use is not easy to fade. Can accurately match the overall style of furniture, whether it is fresh and elegant or rich and bright color requirements, can be met. 6. Environmental hygiene: Acrylic material itself is non-toxic and harmless, and no harmful chemicals are added during the production process, which meets environmental standards. Used for furniture edging, creating a healthy and environmentally friendly home environment for users. 7. Smooth and easy to clean surface: The surface is flat and smooth, not easily stained with dust, oil, and other stains. Daily cleaning only requires gentle wiping with a damp cloth to restore cleanliness and brightness, making it easy to maintain furniture.

Acrylic edge banding strip Acrylic dual color edge banding strip Acrylic environmentally friendly edge banding stripSend Email Details -

Solid Acrylic Two Color Acrylic Edge Banding Strip

Acrylic edge banding has many advantages, including: In terms of appearance High transparency: Acrylic itself has good transparency, and when made into edge banding, it can present a crystal clear effect, especially in furniture designs that pursue simplicity, modernity, and transparency. Using acrylic edge banding can make furniture look more exquisite and high-end, creating a light and open visual experience. • Good glossiness: The surface has a bright luster and high durability. Even after long-term use, it can still maintain a good luster, adding luster to furniture and improving overall aesthetics, making it easy to stand out among many edge banding materials and showcasing a unique sense of quality. • Rich colors: Various colors can be achieved through dyeing and other processes, as well as dual color combinations. Whether it is a bright light color series or a low-key neutral or dark color series, they can be accurately blended to meet the diverse needs of different styles of furniture and decoration scenes for color matching. In terms of material performance Moderate hardness: It not only has a certain degree of hardness, can maintain its own shape well, prevent easy deformation during daily use, but also has a certain degree of flexibility, making it easy to bend, cut and other operations during installation, so that it can adapt to different shapes of board edges, whether it is straight or curved, it can be handled properly. Wear resistance: It has good wear resistance. Compared with some ordinary plastic edge banding strips, acrylic edge banding strips are less prone to obvious scratches and wear marks under frequent daily friction and scratching. They can maintain a good appearance for a long time, extend the service life, and reduce replacement costs. • Chemical corrosion resistance: It has good resistance to common chemicals such as cleaning agents, acidic and alkaline solutions in daily life, and will not be easily corroded, discolored or damaged during use, ensuring its stability of performance. It is suitable for use in various different environments, such as kitchens, bathrooms and other special places, and can also be used normally. Processing and installation aspects Excellent processing performance: It is easy to perform cutting, drilling, hot bending and other processing operations, and is not prone to cracking, breakage and other problems during the processing. This allows workers to easily and quickly process acrylic edge banding according to design requirements in the furniture production process, improving production efficiency and also facilitating the production of furniture with more complex and unique shapes. Easy to install: Generally, it can be installed by pasting or other methods. The adhesive layer on the back has good adhesion and can firmly adhere to the edge of the board. After installation, it fits tightly with the board without the need for complex installation tools or cumbersome installation processes. The operation is simple and easy, reducing installation difficulty and cost. Environmental and health aspects • Good environmental friendliness: Acrylic material itself is relatively environmentally friendly, and under normal use conditions, it will not release substances harmful to human health, which meets the requirements of modern homes for environmentally friendly materials. It can make users feel more at ease and help create a healthy and comfortable indoor environment.

Acrylic edge banding strip two color acrylic edge banding strip solid color acrylic edge banding stripSend Email Details