-

PVC ABS Environmentally Friendly Laser Edge Banding Strip

PVC/ABS laser environmentally friendly edge banding mainly includes the following aspects: In terms of appearance Seamless effect: Laser edge banding technology enables seamless bonding between the edge banding strip and the board, resulting in a more beautiful and natural appearance. Especially for light colored boards such as white and transparent boards such as acrylic, it can present a nearly perfect edge banding effect, improving the overall quality and grade of furniture. Rich colors: PVC/ABS edge banding can be printed with ink and other processes to present a variety of colors and textures, such as wood grain, stone grain, cloth grain, etc., to meet different furniture styles and personalized needs. Performance aspect High bonding strength: After laser activation of the functional layer of the edge banding strip, it is bonded to the board particles' rivets' with high bonding strength, greatly improving the durability of the bonding peel strength and enhancing the durability of the furniture. • Good heat resistance: ABS edge banding itself has high heat resistance and is not easily deformed or melted; Laser edge sealing technology further enhances its heat resistance, allowing furniture to adapt to different temperature environments and extend its service life. Strong light resistance: It has good light resistance and is not easily faded or discolored under long-term light exposure, ensuring that furniture always maintains a good appearance during use.. Waterproof and moisture-proof: effectively prevent moisture from entering the board, protect the board from moisture and deformation, improve the moisture-proof performance of furniture, suitable for various humid environments such as kitchens, bathrooms, etc Processing aspect • Precise and efficient: The laser edge banding equipment can automatically adjust parameters according to the type of edge banding tape, with precise and convenient operation, improving processing efficiency and stability of edge banding quality, and reducing manual operation errors. Reduce pollution: It eliminates processes such as glue coating and anti sticking agent spraying, avoiding the volatilization and pollution of glue. At the same time, there is no need to clean components such as glue pots and scrapers, reducing environmental pollution and making it more environmentally friendly and energy-saving. • Cost reduction: By eliminating the need for a large amount of hot melt adhesive and reducing equipment maintenance and cleaning costs caused by adhesive contamination, processing and labor costs have been lowered. Environmental and health aspects • No glue evaporation: The hot melt adhesive used in traditional edge sealing processes may release harmful substances, while laser edge sealing technology does not require glue, avoiding air pollution caused by glue evaporation and creating a healthier home environment for users. Material Environmental Protection: PVC/ABS materials themselves are relatively environmentally friendly, with minimal impact on the environment and human health during production and use, meeting the requirements of modern eco-friendly homes.

PVC environmentally friendly edge banding strip PVC laser edge banding strip ABS environmentally friendly edge banding stripSend Email Details -

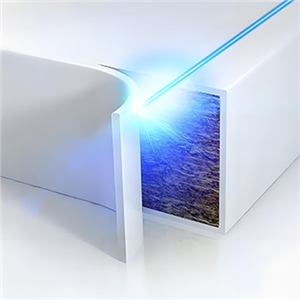

Laser edge banding

Material and Construction • Substrate: Common materials include ABS resin, PP, etc. The Huali Laser Edge banding 2.0 is mainly made of ABS resin as the substrate, which has good performance. Functional layer: also known as "laser coating", located on the back of the edge banding strip, with a thickness usually ranging from 0.15-0.2mm, composed of high melting point polymers, laser photoactive activation substances, etc. It is inert at room temperature and will be instantly activated by laser irradiation.

Send Email Details