News

-

05-29 2025

Dissecting the formula and production issues of PVC edge banding strips

-

01-17 2025

The method of solving the problem of poor plasticization of PVC edge banding by Liyouli

1. Poor plasticization of PVC edge banding (1) There is a toad skin like phenomenon on the surface of the plastic layer. (2) The temperature control is low, the instrument pointer reflects a low temperature, and the actual measured temperature is also low. (3) The surface of the plastic is blackened and has small cracks or poorly plasticized particles. (4) The plastic glue is not sewn well, with a clear mark.

-

01-17 2025

Reasons for discoloration of PVC edge banding

1. Heat, oxygen, light aging discoloration Many people believe that to solve the problem of inconsistent color in PVC edge banding processing, as long as the yellowing profile production line is lowered in processing temperature, the color difference can be reduced. But some people also believe that PVC has a greater impact on yellowing CPE、 Stabilizers, PVC from different batches CPE、 Stabilizers and other main auxiliary materials may have different color differences during processing. In this case, even adding a certain amount of whitening agent or anti-aging agent alone will not have much effect. The main manifestation of discoloration caused by heat, oxygen, and light aging is yellowing of profiles. Some stabilizer manufacturers claim that using their products can reduce the number of parts and lower costs compared to similar manufacturers when promoting their products. Although the results can also produce PVC profiles that appear satisfactory, in the recycling of waste and strict process temperature requirements, due to insufficient thermal stability efficiency, the damage to PVC molecular structure cannot be observed by the naked eye. Therefore, the following situations occur during production: (1) During the processing of PVC edge banding, it was found that the color was not uniform (slight deviation in color is allowed); (2) The profile shows obvious yellowing after heating deformation; (3) The state is good after heating, but the profile becomes gray after being made into doors and windows for a short time. The profile does not turn yellow during normal production, but turns yellow in later window products. In the production process of profiles, when the basic conditions such as raw materials and molds remain unchanged, if the temperature of the plasticizing and homogenization sections is increased by about 5 ℃, the resulting profiles tend to turn yellow, indicating insufficient thermal stability efficiency. Therefore, the amount of heat stabilizer added should be increased, especially when adding whitening agents such as fluorescent whitening agents in the formula. The reason for discoloration of PVC profiles is not obvious due to insufficient heat stabilizer.

-

01-17 2025

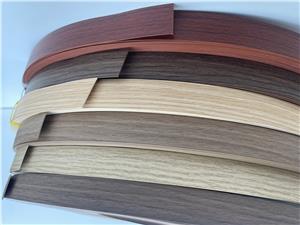

What is PVC furniture edge banding?

PVC edge banding is a thermoplastic coil material mainly made of polyvinyl chloride (PVC), added with plasticizers, stabilizers, lubricants, dyes and other additives, mixed and pressed together. Its surface has patterns such as wood grain, technological pattern, marble, cloth pattern, and solid color, with a soft surface gloss and a realistic and three-dimensional feeling of wood; The surface smoothness and decorative properties can be customized according to customer requirements, with certain heat resistance, chemical resistance, corrosion resistance, and surface hardness. The main function of edge banding is to firmly seal the cross-section of the board, avoiding damage to the board from environmental and usage factors (mainly moisture), and preventing formaldehyde volatilization inside the board, achieving a decorative effect.