News

-

01-17 2025

The method of solving the problem of poor plasticization of PVC edge banding by Liyouli

1. Poor plasticization of PVC edge banding (1) There is a toad skin like phenomenon on the surface of the plastic layer. (2) The temperature control is low, the instrument pointer reflects a low temperature, and the actual measured temperature is also low. (3) The surface of the plastic is blackened and has small cracks or poorly plasticized particles. (4) The plastic glue is not sewn well, with a clear mark.

-

01-17 2025

Questions and answers about edge banding

After a long conversation with the clients, many of them have asked some questions about edge banding. Today, when I have time, I have compiled them for everyone's reference. 1) Folding white refers to the phenomenon of whitening at the bent edge after making a small curved edge on the edge banding strip, and this whitening will not be restored after the edge banding strip is straightened again. This phenomenon is more pronounced for dark edge banding. 2) Bouncing edge, which is prone to produce popping edges when trimming the edge strip. Of course, the reason for the occurrence of jumping edges is not only due to the high content of calcium carbonate powder. When the hot melt adhesive for edge sealing is not properly mixed with the feeding speed, it can cause the edge sealing strip to not fully adhere to the board during trimming, resulting in edge jumping due to the floating of the edge sealing strip. 3) The edge glossiness of the edge banding after trimming and grinding is poor, resulting in a poor appearance effect. At present, low-quality edge banding strips on the market contain over 60% calcium carbonate powder to reduce costs. As for the different equivalent products of the same brand, it is mainly their calcium carbonate powder content. 4) Cracking, due to the high content of calcium carbonate, causes the edge banding to lack toughness and the internal structure to be loose. It will crack under slight external force, especially during transportation at low temperatures.

-

01-17 2025

Reasons for discoloration of PVC edge banding

1. Heat, oxygen, light aging discoloration Many people believe that to solve the problem of inconsistent color in PVC edge banding processing, as long as the yellowing profile production line is lowered in processing temperature, the color difference can be reduced. But some people also believe that PVC has a greater impact on yellowing CPE、 Stabilizers, PVC from different batches CPE、 Stabilizers and other main auxiliary materials may have different color differences during processing. In this case, even adding a certain amount of whitening agent or anti-aging agent alone will not have much effect. The main manifestation of discoloration caused by heat, oxygen, and light aging is yellowing of profiles. Some stabilizer manufacturers claim that using their products can reduce the number of parts and lower costs compared to similar manufacturers when promoting their products. Although the results can also produce PVC profiles that appear satisfactory, in the recycling of waste and strict process temperature requirements, due to insufficient thermal stability efficiency, the damage to PVC molecular structure cannot be observed by the naked eye. Therefore, the following situations occur during production: (1) During the processing of PVC edge banding, it was found that the color was not uniform (slight deviation in color is allowed); (2) The profile shows obvious yellowing after heating deformation; (3) The state is good after heating, but the profile becomes gray after being made into doors and windows for a short time. The profile does not turn yellow during normal production, but turns yellow in later window products. In the production process of profiles, when the basic conditions such as raw materials and molds remain unchanged, if the temperature of the plasticizing and homogenization sections is increased by about 5 ℃, the resulting profiles tend to turn yellow, indicating insufficient thermal stability efficiency. Therefore, the amount of heat stabilizer added should be increased, especially when adding whitening agents such as fluorescent whitening agents in the formula. The reason for discoloration of PVC profiles is not obvious due to insufficient heat stabilizer.

-

01-17 2025

Five important factors in the use of edge banding

1、Base material for edge sealing hot melt adhesive 2、Viscosity of edge sealing hot melt adhesive 3、Density of edge sealing hot melt adhesive 4、Density of edge sealing hot melt adhesive 5、Density of edge sealing hot melt adhesive

-

01-17 2025

The basic essentials of edge banding technology

Basic requirements for substrate 1 Materials such as medium density fiberboard or particleboard are used as the base material for edge wrapping, but due to the low cost of particleboard, it is often used as the base material for edge wrapping components. The main technical indicators of particleboard suitable for edge wrapping are that when the thickness of the particleboard is greater than 10mm, its warpage should be less than or equal to 0.5%; The internal bonding strength should meet the requirements of the national standard (92) for Class A high-quality and first-class particleboard, so that the bonding strength between the surface material and the particleboard during edge wrapping can achieve good results. The density of particleboard should be controlled between 0.6-0.85 grams per cubic centimeter, which is beneficial for milling the edge profile and can achieve high surface smoothness, while reducing the penetration of adhesive and ensuring sufficient adhesive amount during edge bonding. The substrate should be sandblasted before use to control the thickness tolerance within 0.1 mm of the soil. Basic requirements for 2-layer materials The surface layer material should generally have good bending performance under heating conditions. The direct continuous edging machine can use a variety of edging materials, such as low-pressure melamine veneer CPL、 Paint film paper and veneer materials, but the commonly used surface material is low-pressure melamine adhesive panel. The thickness of the surface material for edge wrapping using a direct continuous post forming edge wrapping machine is generally less than 0.35mm, and the bending performance and strength of the surface material have a significant impact on the quality of the edge wrapping. Basic requirements for balanced layer materials To ensure that the components do not warp, a balancing layer must be glued to the back of the components. The material used for the balance layer should be the same as the surface layer material, but due to the high price of the surface layer material, ordinary low-pressure melamine veneer or other flexible materials are generally used for the balance layer material. In actual production, warping may occur after edge wrapping, mainly due to improper use of surface and balance layer materials. Only when the thickness of the surface layer material multiplied by the elastic modulus of the surface layer material is equal to the thickness of the balance layer material multiplied by the elastic modulus of the balance layer material, will there be no warping of the post formed edge wrapped components.

-

01-17 2025

The relationship between edge banding and hot melt adhesive

Hot melt adhesive is increasingly used in furniture edge sealing, but there are also many difficulties encountered during use. Below is a specific analysis of the common problems of adhesive bonding with hot melt adhesive for edge sealing: 1、 Edge sealing detachment: Check whether the operation is correct, operate according to the machine operation requirements and the correct parameters of hot melt adhesive; Check if the edge banding machine is functioning properly; Is the back coating of the edge banding normal? If it is a wooden edge banding, check whether it is a multi fat tree species or whether the moisture of the non-woven fabric on the back is qualified; Is the hot melt type suitable; Is there any quality issue with the hot melt solution. 2、 Insufficient edge sealing strength: whether the type of hot melt adhesive used is appropriate; Is the board too fluffy or unqualified, and is the stacking time of the board too long causing too much dust at the ports; Whether the edge banding is contaminated; Whether the back coating of the edge banding is uniform; The temperature of the hot melt adhesive is incorrect, the pressure of the edge banding machine is insufficient, and the operating pressure of the manual edge banding machine relies on manual control, which is particularly prone to the above problems; The operating environment temperature is too low. 3、 Thick glue line: The model used is incorrect. For example, fast glue is used on a slow machine and is not bonded, while hot melt glue has already started to solidify, resulting in loose compression; The precision of sheet metal processing is insufficient, the sawing is not good, and the cutting edge is not straight enough; The edge banding is deformed and not horizontal or curved enough; The pressure wheel of the edge banding machine is worn, and the pressure is uneven up and down, resulting in thick adhesive lines on one side; The pressure of the edge banding machine is insufficient and cannot be tightened. A pressure of 3-5kg/cm2 is required; The amount of glue applied is too large, causing glue to overflow. 4、 Wire drawing contaminated sheet: Poor quality of hot melt adhesive; Improper selection of models, such as using slow glue on high-speed machines, prolonged opening time of hot melt adhesive, and slow drying of glue; The temperature of the hot melt adhesive is too high, or the speed of the edge banding machine is too fast; The amount of glue applied is too large; The quality of the glue roller is poor, and it cannot be evenly coated or adjusted reasonably. 5、 After spraying the paint for a few days after edge sealing, it falls off: the edge sealing has not reached high bonding strength. Check whether the operation is reasonable or whether the quality of the hot melt adhesive is qualified; Spray paint peeling off the wooden veneer, check if there is too much grease on the back of the veneer or if the non-woven fabric (paper) on the back is too wet; Spray paint peeling off the wooden veneer, check whether the pores of the veneer are too large, and whether the solvent of the paint penetrates into the adhesive and damages the adhesive film; The quality of hot melt adhesive does not meet the requirements, and low-temperature adhesive is not suitable for use in such processes; Poor handling during edge sealing results in thick adhesive lines, leading to poor sealing and solvent penetration into the adhesive film, which can damage its strength.

-

01-17 2025

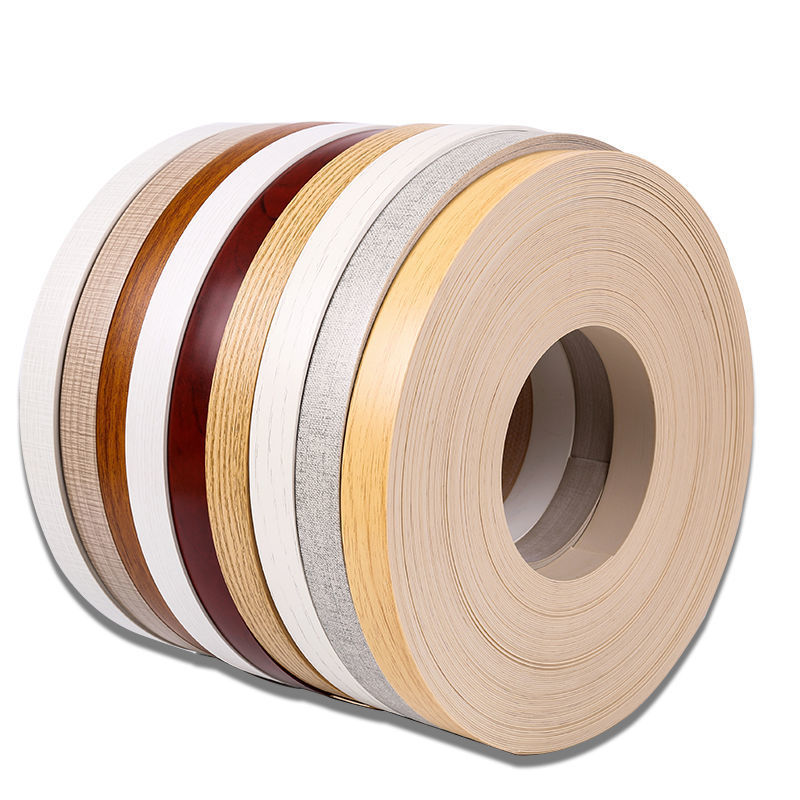

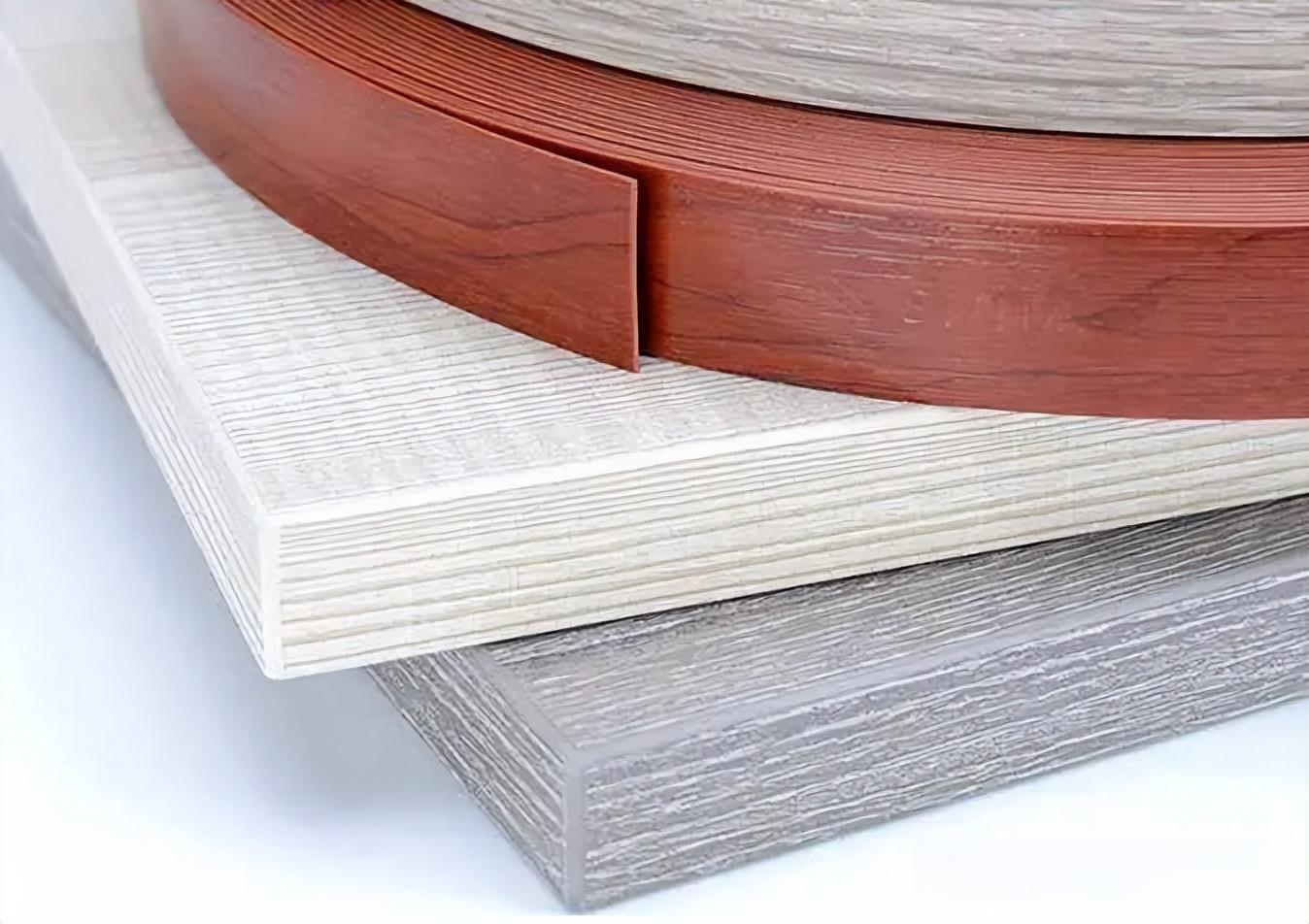

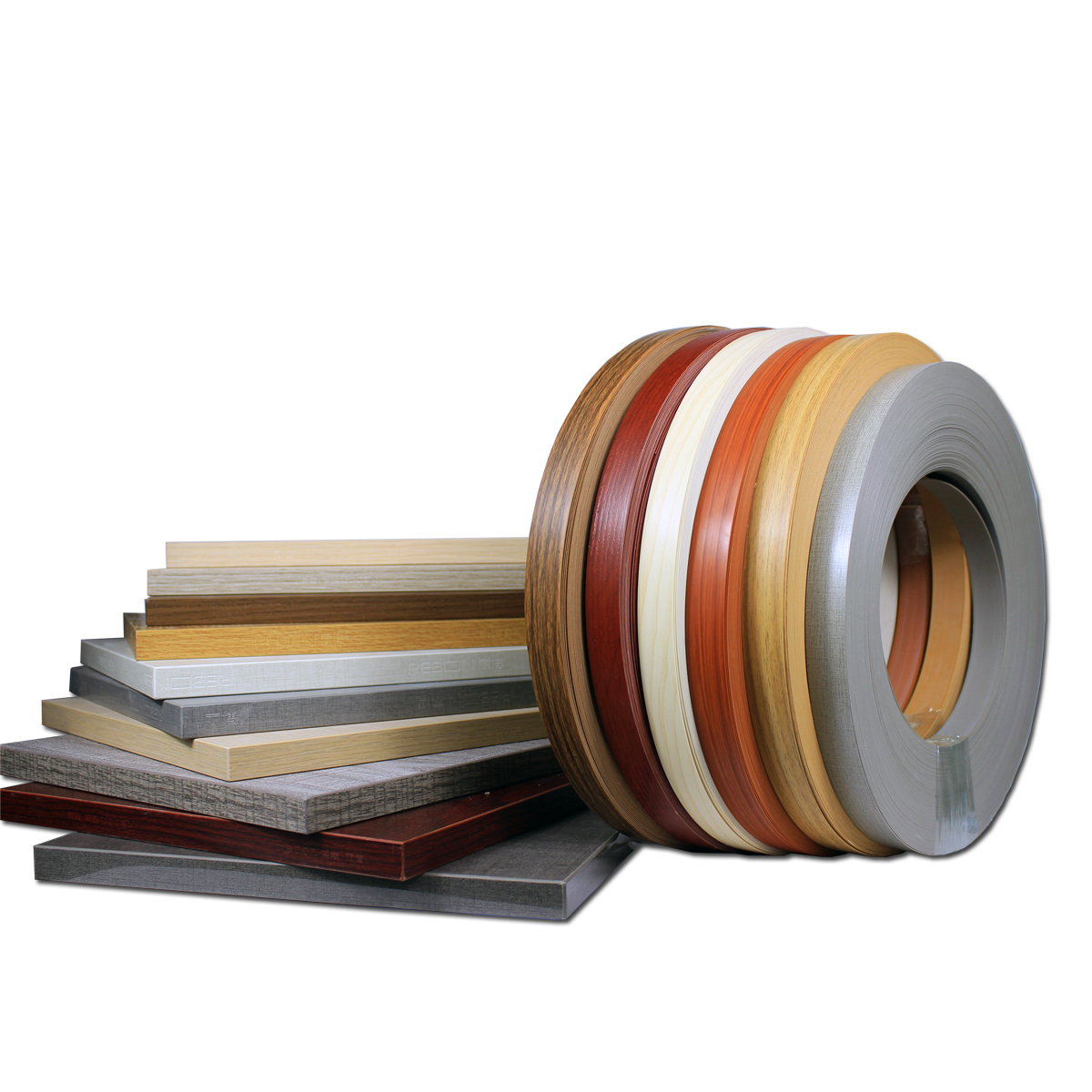

What is PVC furniture edge banding?

PVC edge banding is a thermoplastic coil material mainly made of polyvinyl chloride (PVC), added with plasticizers, stabilizers, lubricants, dyes and other additives, mixed and pressed together. Its surface has patterns such as wood grain, technological pattern, marble, cloth pattern, and solid color, with a soft surface gloss and a realistic and three-dimensional feeling of wood; The surface smoothness and decorative properties can be customized according to customer requirements, with certain heat resistance, chemical resistance, corrosion resistance, and surface hardness. The main function of edge banding is to firmly seal the cross-section of the board, avoiding damage to the board from environmental and usage factors (mainly moisture), and preventing formaldehyde volatilization inside the board, achieving a decorative effect.

-

01-17 2025

The advantages of ABS edge banding

1. ABS edge banding does not add any fillers (such as calcium carbonate) during the production process, so the rounded corners are smooth, shiny, and textured after trimming, and the surface has strong impact resistance. 2. ABS edge banding has good dimensional stability and only undergoes shrinkage deformation at a high temperature of 99 degrees Celsius. 3. ABS edge banding has strong resistance to chemical corrosion and is constantly renewed over time. Coffee, soy sauce, alcohol, and other substances will not cause any damage to its surface. 4. ABS edge banding has no irritating odor. 5. ABS edge banding can be directly burned at high temperatures without air pollution, which is beneficial for environmental protection.