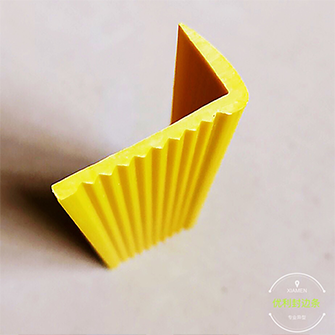

PVC Plastic Special Shaped Extruded Parts

Brand Youli edge banding strip

Product origin Xiamen, China

Delivery time 7-10Day

Supply capacity Can produce 300000 meters per day

MOQ Irregular extruded parts starting from 5000 meters

PVC non-standard extruded parts have the following advantages:

High degree of customization

1. Flexible and diverse shapes

Various complex and unique shapes can be extruded according to different usage and design requirements, almost without being limited by conventional geometric shapes. For example, in the field of architectural decoration, various shapes of lines such as right angle corner protection signs and opposite sex combinations can be extruded for decorating walls and ceilings, creating a unique visual effect; In terms of industrial components, it is also possible to manufacture special-shaped connecting parts, sealing parts, etc. that are suitable for special equipment structures to meet specific mechanical fit requirements.

2. Sizes can be customized as needed

Not only can the shape be customized, but its size can also be precisely adjusted according to the specific specifications of the actual project. Whether it is small and exquisite electronic product shell accessories or ultra long decorative profiles for large buildings, PVC shaped parts of corresponding sizes can be obtained through customized extrusion processes, which are well adapted to the differentiated size requirements of different application scenarios.

Good material properties

1. Good chemical stability

PVC (polyvinyl chloride) itself has excellent chemical stability and has a certain tolerance to many common chemicals, such as acidic and alkaline solutions, organic solvents, etc. This enables PVC non-standard extruded parts to maintain stable performance for a long time in environments with chemical corrosion risks, such as pipeline seals in chemical workshops and equipment protective components in laboratories, effectively resisting the erosion of chemical substances and extending their service life.

2. Adjustable mechanical properties

By adding different additives and optimizing the formula, the mechanical properties of PVC extruded parts can be flexibly adjusted. For example, adding plasticizers appropriately can improve the flexibility of materials, making them suitable for manufacturing products that require bending and folding, such as bendable wire conduit; Adding reinforcing fillers can also enhance its hardness and strength, making it suitable for making structural components that need to withstand certain pressure or weight, such as irregular frames for doors and windows, which can meet the mechanical performance requirements of components under different working conditions.

3. Strong weather resistance

After special formulation and treatment, PVC material has good weather resistance and can be used under different climatic conditions. Whether exposed to long-term outdoor sunlight, rain, sandstorms, such as outdoor billboard frames, building exterior wall decorative strips, or in environments with large temperature and humidity changes indoors, it is not easy to experience fading, deformation, cracking, and other problems, and can maintain good appearance and performance.

Production efficiency and cost advantages

1. High continuous extrusion production efficiency

When using extrusion technology to produce PVC shaped parts, as long as the mold and other preliminary preparations are ready, continuous and efficient production can be achieved. After being heated and plasticized in the extruder, the material is continuously extruded through the mold, resulting in a considerable output per unit time. Compared with some manufacturing methods that require multiple complex processes and single piece processing, it greatly improves production efficiency, especially suitable for mass customization production.

2. Outstanding cost-effectiveness

PVC raw materials have a wide range of sources, relatively low prices, and relatively simple extrusion processes. The equipment investment and operating costs are at a moderate level in the manufacturing industry. Overall, the ability to produce non-standard shaped extruded parts that meet various requirements at a relatively economical cost makes the product highly competitive in the market, which is beneficial for manufacturers to control costs and for buyers to reduce procurement costs.

Environmental and safety features

1. Recyclable and reusable

PVC material is a recyclable material. After appropriate recycling processes, discarded PVC non-standard extruded parts can be reprocessed into new PVC products, which conforms to the current concept of resource recycling and sustainable development. It helps reduce dependence on primary resources and minimize the impact of waste on the environment.

2. Adjustable flame retardant performance

By adding appropriate flame retardants to the formula, PVC extruded parts can have varying degrees of flame retardancy. PVC decorative profiles and wire conduits used in public buildings such as shopping malls, hospitals, and subway stations with high fire prevention requirements can effectively reduce the risk of fire spread in the event of a fire, ensuring the safety of personnel and property.

Easy installation and maintenance

1. Easy installation

Due to the fact that PVC non-standard extruded parts are often lightweight, and many products are designed with structural features that are easy to install, such as snap fasteners, slots, and other connection designs, they do not require complex tools and professional skills in the actual installation process. Ordinary workers can easily complete the operation according to the installation instructions, which can effectively save installation time and labor costs.

2. Low maintenance costs

Its surface is usually smooth and not easily contaminated with dirt. Daily cleaning is simple and only requires wiping with a damp cloth. Moreover, as mentioned earlier, it has good stability and durability, with a relatively low probability of failure or damage. Even if there is partial damage, replacement is relatively easy, and the overall maintenance cost is not high, reducing concerns during use.

PVC non-standard extruded parts have the following advantages:

High degree of customization

1. Flexible and diverse shapes

Various complex and unique shapes can be extruded according to different usage and design requirements, almost without being limited by conventional geometric shapes. For example, in the field of architectural decoration, various shapes of lines such as right angle corner protection signs and opposite sex combinations can be extruded for decorating walls and ceilings, creating a unique visual effect; In terms of industrial components, it is also possible to manufacture special-shaped connecting parts, sealing parts, etc. that are suitable for special equipment structures to meet specific mechanical fit requirements.

2. Sizes can be customized as needed

Not only can the shape be customized, but its size can also be precisely adjusted according to the specific specifications of the actual project. Whether it is small and exquisite electronic product shell accessories or ultra long decorative profiles for large buildings, PVC shaped parts of corresponding sizes can be obtained through customized extrusion processes, which are well adapted to the differentiated size requirements of different application scenarios.

Good material properties

1. Good chemical stability

PVC (polyvinyl chloride) itself has excellent chemical stability and has a certain tolerance to many common chemicals, such as acidic and alkaline solutions, organic solvents, etc. This enables PVC non-standard extruded parts to maintain stable performance for a long time in environments with chemical corrosion risks, such as pipeline seals in chemical workshops and equipment protective components in laboratories, effectively resisting the erosion of chemical substances and extending their service life.

2. Adjustable mechanical properties

By adding different additives and optimizing the formula, the mechanical properties of PVC extruded parts can be flexibly adjusted. For example, adding plasticizers appropriately can improve the flexibility of materials, making them suitable for manufacturing products that require bending and folding, such as bendable wire conduit; Adding reinforcing fillers can also enhance its hardness and strength, making it suitable for making structural components that need to withstand certain pressure or weight, such as irregular frames for doors and windows, which can meet the mechanical performance requirements of components under different working conditions.

3. Strong weather resistance

After special formulation and treatment, PVC material has good weather resistance and can be used under different climatic conditions. Whether exposed to long-term outdoor sunlight, rain, sandstorms, such as outdoor billboard frames, building exterior wall decorative strips, or in environments with large temperature and humidity changes indoors, it is not easy to experience fading, deformation, cracking, and other problems, and can maintain good appearance and performance.

Production efficiency and cost advantages

1. High continuous extrusion production efficiency

When using extrusion technology to produce PVC shaped parts, as long as the mold and other preliminary preparations are ready, continuous and efficient production can be achieved. After being heated and plasticized in the extruder, the material is continuously extruded through the mold, resulting in a considerable output per unit time. Compared with some manufacturing methods that require multiple complex processes and single piece processing, it greatly improves production efficiency, especially suitable for mass customization production.

2. Outstanding cost-effectiveness

PVC raw materials have a wide range of sources, relatively low prices, and relatively simple extrusion processes. The equipment investment and operating costs are at a moderate level in the manufacturing industry. Overall, the ability to produce non-standard shaped extruded parts that meet various requirements at a relatively economical cost makes the product highly competitive in the market, which is beneficial for manufacturers to control costs and for buyers to reduce procurement costs.

Environmental and safety features

1. Recyclable and reusable

PVC material is a recyclable material. After appropriate recycling processes, discarded PVC non-standard extruded parts can be reprocessed into new PVC products, which conforms to the current concept of resource recycling and sustainable development. It helps reduce dependence on primary resources and minimize the impact of waste on the environment.

2. Adjustable flame retardant performance

By adding appropriate flame retardants to the formula, PVC extruded parts can have varying degrees of flame retardancy. PVC decorative profiles and wire conduits used in public buildings such as shopping malls, hospitals, and subway stations with high fire prevention requirements can effectively reduce the risk of fire spread in the event of a fire, ensuring the safety of personnel and property.

Easy installation and maintenance

1. Easy installation

Due to the fact that PVC non-standard extruded parts are often lightweight, and many products are designed with structural features that are easy to install, such as snap fasteners, slots, and other connection designs, they do not require complex tools and professional skills in the actual installation process. Ordinary workers can easily complete the operation according to the installation instructions, which can effectively save installation time and labor costs.

2. Low maintenance costs

Its surface is usually smooth and not easily contaminated with dirt. Daily cleaning is simple and only requires wiping with a damp cloth. Moreover, as mentioned earlier, it has good stability and durability, with a relatively low probability of failure or damage. Even if there is partial damage, replacement is relatively easy, and the overall maintenance cost is not high, reducing concerns during use.