PVC finished edge banding strip

Brand Youli edge banding strip

Product origin Xiamen, China

Delivery time 7-10Day

Supply capacity Can produce 300000 meters per day

MOQ 10000M

Product advantages

1. PVC edge banding has a soft color that can perfectly blend with matte furniture and other surfaces, creating a visually coordinated and comfortable look.

2. PVC edge banding is heat-resistant, chemical resistant, corrosion-resistant, and achieves decorative effects when the surface has a certain degree of hardness.

3. PVC edge banding products have a smooth surface and uniform thickness. The commonly used product thickness is between 0.4MM-3MM, and the width can be customized according to customer needs.

4. PVC edge banding is safe and environmentally friendly, making it an ideal choice for homes and offices. It has a long lifespan and can meet the long-term needs of customers.

Product application:

Furniture, offices, shelves, exhibition stands, kitchenware, teaching equipment, teaching aids, RVs, laboratories, and more. The thickness ranges from 0.4 to 3mm, and the width ranges from 12mm to 150mm.

Main features of the product:

Smooth surface, no bubbles, no stretch marks, moderate glossiness, smooth surface and back, uniform thickness, consistent width, reasonable hardness, high elasticity, good quality, strong wear resistance, edge color close to surface color, no whitening, good glossiness, and coordinated overall texture matching of furniture products.

Look at the color and surface roughness of the edge banding, and the color of the surface of a good edge banding is also important. Whether the color is similar and bright to the customized product. If the surface is rough and has scratches, the quality is definitely not much better, which is the surface quality problem of the edge banding. It has little to do with the quality of the internal material of the edge banding strip, but mainly with the production process of the edge banding strip factory and the production technical skills of the employees. A good edge banding is: the surface must be smooth, with no or very few bubbles, no or very few wrinkles, moderate glossiness, and not too shiny or too matte (unless there are special requirements).

Characteristics and processing technology of PVC edge banding:

The main function of PVC edge banding is to seal the cross-section of the board, avoiding damage to the board caused by environmental and usage factors (mainly moisture), preventing formaldehyde volatilization inside the board, and achieving a beautiful decorative effect. Edge banding is mainly used for edge banding of panel furniture. The main raw material is PVC. Compared with ABS edge sealing, edge sealing is cheaper and has better edge sealing effect. Compared with melamine edge banding, edge banding is durable, not easily deformed or damaged. Let's learn about its characteristics and processing technology.

There are various styles of PVC edge banding available on the market, including T-shaped, D-type, F-type, glass clip, door and window edge banding, stationery edge banding, and protective anti-collision tape. It can also determine whether the irregular edge banding is environmentally friendly, UV resistant, anti-static, temperature resistant, and cold resistant. Protection can be provided according to different usage environments and customer specific requirements.

The production process route of edge banding products is formed by a series of production line activities, including processing, transportation, assembly, and inspection, starting from the entry of raw materials into the production site. The narrow definition of edge banding production line is a production organization form organized according to the principle of object to complete the product production process. It is equipped with various equipment and workers required for the production of a certain product according to the principle of product specialization, responsible for producing a certain product and completing all manufacturing work of a certain product. The same labor object performs different processes.

The main reason for the aging of PVC edge banding is that it has a long light aging time under natural climatic conditions. Therefore, in order to quickly evaluate and predict the anti photoaging performance of PVC materials, obtain experimental results in a short period of time, and provide theoretical basis and basic data for the evaluation and prediction of surface photoaging performance, a surface photoaging simulation experimental system was established.

The main components of PVC edge banding are as follows:

PVC edge banding is a thermoplastic resin mainly composed of PVC resin, with a certain amount of stabilizer, calcium carbonate, coloring agent, antioxidant, etc. added, and then formed through mixing, rolling and other processes. It is a homopolymer of vinyl chloride.

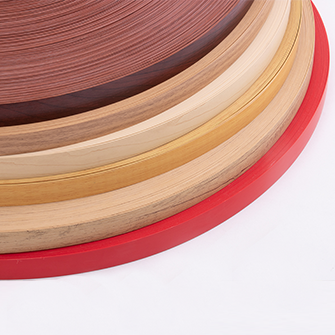

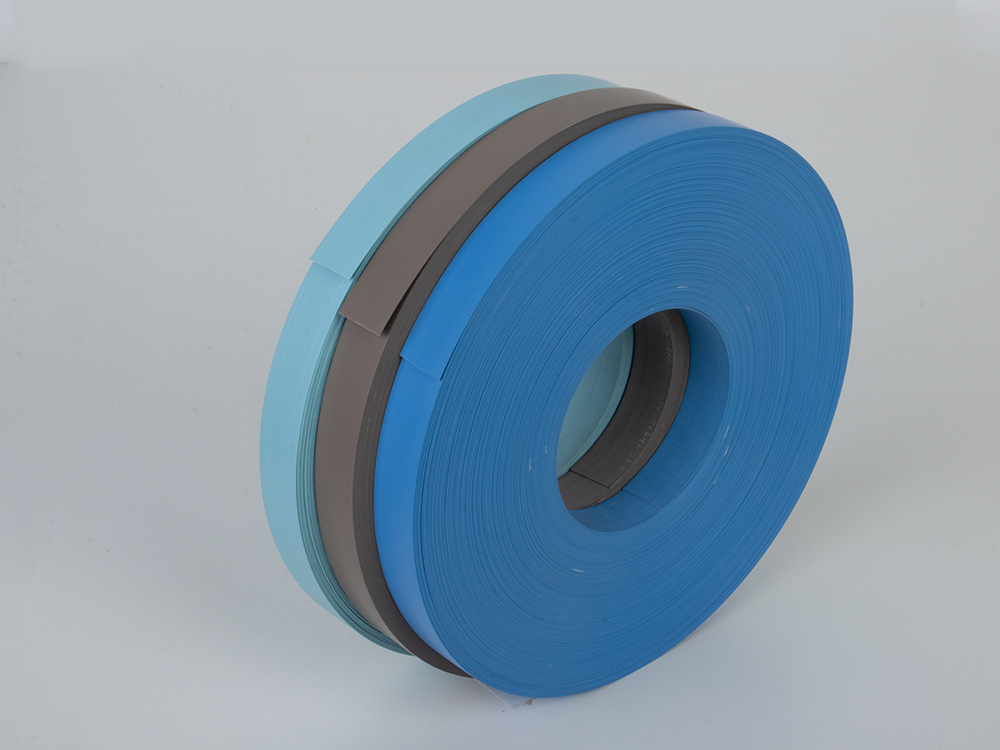

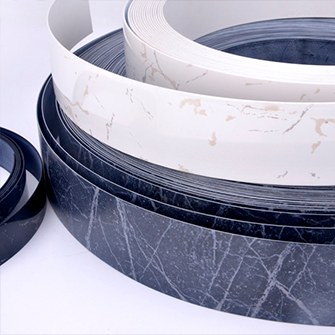

PVC edge banding can be divided into wood grain edge banding and solid color edge banding according to color. Solid color PVC edge banding refers to the common colors in our daily lives such as red, yellow, blue, green, etc., which means monochrome. Wood grain PVC edge banding is printed on the surface of the edge banding with paint, forming a wood grain like effect.

What are the specific advantages of PVC edge banding

1. It is much lighter than metal box organic glass.

2. The main component of PVC edge banding is plastic, which has strong plasticity and can be changed after heating or pressing. Various shapes of edge banding can be formed through processing techniques such as extrusion.

3. Price fluctuations are much smaller than in the metal industry.

4. It is not easy to rot or rust.

5. High temperature and cold resistance.