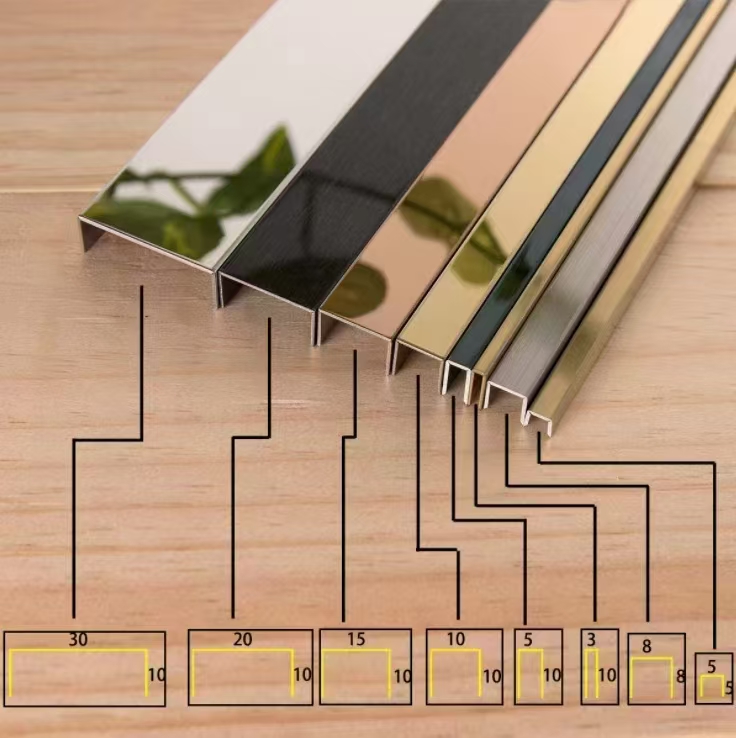

Plastic Aluminum Alloy Edge Banding

Brand Youli edge banding strip

Product origin Xiamen, China

Delivery time 7-10Day

Supply capacity Can produce 300000 meters per day

MOQ 10000M

Introduction to ABS/PVC mirror stainless steel edge banding:

Appearance features

Mirror effect: It has excellent mirror reflection characteristics, with a smooth and bright surface like a mirror, which can clearly reflect surrounding objects and scenes. This mirror effect greatly enhances its decorative value, making furniture or decorative parts appear exquisite and high-end, creating a fashionable, modern, and luxurious visual atmosphere.

• Color and Gloss: In terms of color, classic metallic colors such as silver and gold are commonly seen, which inherently carry a sense of nobility. Combined with the mirror like luster, they can shine brightly under different lighting conditions and become the visual focus of the space. And the color retention is high, and it is not easy to fade after long-term use, which can continue to show a bright appearance effect.

Material characteristics

Advantages of composite materials: Made of ABS, PVC, and mirror stainless steel composite, it combines the advantages of multiple materials. ABS material has high hardness, strong dimensional stability, wear and scratch resistance, which can ensure that the edge banding is not easily deformed during use, maintaining a good shape and appearance; PVC material has good flexibility and easy processing, which is conducive to various shapes of bending, cutting and other processing operations, while the cost is relatively low; Mirror stainless steel endows the entire edge banding with excellent metallic texture, high strength, and excellent corrosion resistance.

Rich texture: When touched, it has a certain flexibility of plastic material and a clear sense of the tough texture of metal. This unique texture combination makes it stand out among many edge banding strips, adding a unique sense of hierarchy and quality to furniture and other items.

Processing features

• Good processing adaptability: Due to the presence of PVC material, the overall edge banding has good plasticity. During the processing, the length can be cut using conventional cutting tools, and the incision is relatively flat without serious roughness or cracking. And when facing curved edges of the board, it can use its flexibility to bend appropriately, making it fit tightly and easy to meet the edge sealing needs of furniture or decorative objects of different shapes.

• Installation convenience: It is usually equipped with a suitable adhesive layer. When installing, simply align it accurately with the part that needs to be sealed, apply appropriate pressure, and it can be firmly attached to the edge of the board. The operation is simple and fast, without the need for complex professional tools or cumbersome installation processes, effectively improving installation efficiency. It is suitable for wide applications in furniture manufacturing and interior decoration.

Durable features

Strong wear resistance: Thanks to the wear resistance of ABS and the property of mirror stainless steel that is not easily scratched, this edge banding can withstand frequent friction, touch and other situations in daily use. The surface is not easy to have obvious scratches and can maintain a mirror like smooth appearance for a long time, thereby extending its service life and reducing the frequency of replacement.

Excellent corrosion resistance: The mirror stainless steel material provides strong resistance to common chemicals in daily life, such as oil stains in the kitchen, cleaning agents, water stains in the bathroom, acid and alkali solutions, etc. It will not be easily corroded, rusted or discolored, ensuring stable performance in different usage environments (especially humid and chemical pollution risk environments) and maintaining good appearance and function.

Environmental characteristics

Environmental compliance: Our company adheres to relevant environmental standards for the production of ABS/PVC mirror stainless steel edge banding strips. For example, we strictly control the release of harmful substances such as formaldehyde in the plastic part, and ensure that the stainless steel material does not contain harmful heavy metals, so that its impact on human health and the environment when used indoors is minimal, meeting the requirements of modern home and interior decoration for environmentally friendly materials.

Introduction to ABS/PVC mirror stainless steel edge banding:

Appearance features

Mirror effect: It has excellent mirror reflection characteristics, with a smooth and bright surface like a mirror, which can clearly reflect surrounding objects and scenes. This mirror effect greatly enhances its decorative value, making furniture or decorative parts appear exquisite and high-end, creating a fashionable, modern, and luxurious visual atmosphere.

• Color and Gloss: In terms of color, classic metallic colors such as silver and gold are commonly seen, which inherently carry a sense of nobility. Combined with the mirror like luster, they can shine brightly under different lighting conditions and become the visual focus of the space. And the color retention is high, and it is not easy to fade after long-term use, which can continue to show a bright appearance effect.

Material characteristics

Durable features

Strong wear resistance: Thanks to the wear resistance of ABS and the property of mirror stainless steel that is not easily scratched, this edge banding can withstand frequent friction, touch and other situations in daily use. The surface is not easy to have obvious scratches and can maintain a mirror like smooth appearance for a long time, thereby extending its service life and reducing the frequency of replacement.

Excellent corrosion resistance: The mirror stainless steel material provides strong resistance to common chemicals in daily life, such as oil stains in the kitchen, cleaning agents, water stains in the bathroom, acid and alkali solutions, etc. It will not be easily corroded, rusted or discolored, ensuring stable performance in different usage environments (especially humid and chemical pollution risk environments) and maintaining good appearance and function.

Environmental characteristics

Environmental compliance: Our company adheres to relevant environmental standards for the production of ABS/PVC mirror stainless steel edge banding strips. For example, we strictly control the release of harmful substances such as formaldehyde in the plastic part, and ensure that the stainless steel material does not contain harmful heavy metals, so that its impact on human health and the environment when used indoors is minimal, meeting the requirements of modern home and interior decoration for environmentally friendly materials.

Advantages of composite materials: Made of ABS, PVC, and mirror stainless steel composite, it combines the advantages of multiple materials. ABS material has high hardness, strong dimensional stability, wear and scratch resistance, which can ensure that the edge banding is not easily deformed during use, maintaining a good shape and appearance; PVC material has good flexibility and easy processing, which is conducive to various shapes of bending, cutting and other processing operations, while the cost is relatively low; Mirror stainless steel endows the entire edge banding with excellent metallic texture, high strength, and excellent corrosion resistance.

Rich texture: When touched, it has a certain flexibility of plastic material and a clear sense of the tough texture of metal. This unique texture combination makes it stand out among many edge banding strips, adding a unique sense of hierarchy and quality to furniture and other items.

Processing features

• Good processing adaptability: Due to the presence of PVC material, the overall edge banding has good plasticity. During the processing, the length can be cut using conventional cutting tools, and the incision is relatively flat without serious roughness or cracking. And when facing curved edges of the board, it can use its flexibility to bend appropriately, making it fit tightly and easy to meet the edge sealing needs of furniture or decorative objects of different shapes.

• Installation convenience: It is usually equipped with a suitable adhesive layer. When installing, simply align it accurately with the part that needs to be sealed, apply appropriate pressure, and it can be firmly attached to the edge of the board. The operation is simple and fast, without the need for complex professional tools or cumbersome installation processes, effectively improving installation efficiency. It is suitable for wide applications in furniture manufacturing and interior decoration.