News

-

08-20 2025

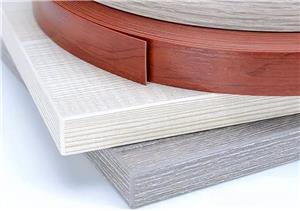

Hot melt adhesive for automatic edge sealing of high-temperature furniture

-

02-12 2025

The future development prospects of the edge banding factory

The future development trend of edge banding manufacturers is influenced by various factors, as follows: In terms of market demand The demand for personalized customization is growing: Consumers' demand for personalized and differentiated home furnishings is constantly increasing. Edge banding manufacturers need to provide more colors, textures, materials, and special shapes of edge banding, such as handle free, curved, and irregular edge banding, to meet different design styles and functional requirements. The demand for integration is highlighted: "Integration of board and edge" requires that the color, texture, and even touch of the edge banding and board be consistent, and the market demand for edge banding that can achieve seamless connection and strong overall feeling is increasing. In terms of technological innovation • Edge banding technology upgrade: The application of new edge banding technologies such as laser edge banding will become increasingly widespread. Edge banding manufacturers need to develop laser edge banding products that are compatible with them, such as Huali 2.0 laser edge banding from Huali Corporation, which has a built-in laser functional layer at the bottom and can achieve seamless edge banding. • Material and process innovation: Continuously exploring and developing new edge banding materials, such as those with better wear resistance, water resistance, chemical resistance, and other properties. At the same time, improving production processes, enhancing production efficiency and product quality, and reducing costs, such as upgrading extrusion processes to achieve automated winding and cutting. In terms of environmental policies Stricter standards: Countries and regions have increasingly strict environmental requirements for home products. Edge banding manufacturers need to use more environmentally friendly raw materials and production processes to ensure that their products meet relevant environmental standards, such as E1 level, ENF level, and other formaldehyde emission standards. Green production has become inevitable: In the production process, manufacturers will use more clean energy, reduce the discharge of wastewater, exhaust gas, and waste residue, and achieve green production to meet environmental policy requirements and consumer demand for green products. In terms of industry competition • Increased brand competition: With fierce market competition, brand awareness and reputation will become important factors for consumers to choose edge banding products. Manufacturers need to strengthen brand building, enhance brand image and influence. Industry chain integration trend: Some powerful edge banding manufacturers may extend upstream, integrate raw material supply, and reduce procurement costs; Expand downstream, establish closer cooperation with furniture production enterprises, provide one-stop solutions, and enhance market competitiveness. In terms of digitization and intelligence Intelligent production: By utilizing advanced production equipment and automation technology, the production process can be made intelligent and automated, improving production efficiency and product quality stability, and reducing labor costs. • Digital marketing: expand sales channels, improve brand awareness and product exposure, and better meet customer needs through Internet platforms and digital marketing means, such as e-commerce platforms, social media, online exhibitions, etc.

-

01-17 2025

Five important factors in the use of edge banding

1、Base material for edge sealing hot melt adhesive 2、Viscosity of edge sealing hot melt adhesive 3、Density of edge sealing hot melt adhesive 4、Density of edge sealing hot melt adhesive 5、Density of edge sealing hot melt adhesive

-

01-17 2025

The relationship between edge banding and hot melt adhesive

Hot melt adhesive is increasingly used in furniture edge sealing, but there are also many difficulties encountered during use. Below is a specific analysis of the common problems of adhesive bonding with hot melt adhesive for edge sealing: 1、 Edge sealing detachment: Check whether the operation is correct, operate according to the machine operation requirements and the correct parameters of hot melt adhesive; Check if the edge banding machine is functioning properly; Is the back coating of the edge banding normal? If it is a wooden edge banding, check whether it is a multi fat tree species or whether the moisture of the non-woven fabric on the back is qualified; Is the hot melt type suitable; Is there any quality issue with the hot melt solution. 2、 Insufficient edge sealing strength: whether the type of hot melt adhesive used is appropriate; Is the board too fluffy or unqualified, and is the stacking time of the board too long causing too much dust at the ports; Whether the edge banding is contaminated; Whether the back coating of the edge banding is uniform; The temperature of the hot melt adhesive is incorrect, the pressure of the edge banding machine is insufficient, and the operating pressure of the manual edge banding machine relies on manual control, which is particularly prone to the above problems; The operating environment temperature is too low. 3、 Thick glue line: The model used is incorrect. For example, fast glue is used on a slow machine and is not bonded, while hot melt glue has already started to solidify, resulting in loose compression; The precision of sheet metal processing is insufficient, the sawing is not good, and the cutting edge is not straight enough; The edge banding is deformed and not horizontal or curved enough; The pressure wheel of the edge banding machine is worn, and the pressure is uneven up and down, resulting in thick adhesive lines on one side; The pressure of the edge banding machine is insufficient and cannot be tightened. A pressure of 3-5kg/cm2 is required; The amount of glue applied is too large, causing glue to overflow. 4、 Wire drawing contaminated sheet: Poor quality of hot melt adhesive; Improper selection of models, such as using slow glue on high-speed machines, prolonged opening time of hot melt adhesive, and slow drying of glue; The temperature of the hot melt adhesive is too high, or the speed of the edge banding machine is too fast; The amount of glue applied is too large; The quality of the glue roller is poor, and it cannot be evenly coated or adjusted reasonably. 5、 After spraying the paint for a few days after edge sealing, it falls off: the edge sealing has not reached high bonding strength. Check whether the operation is reasonable or whether the quality of the hot melt adhesive is qualified; Spray paint peeling off the wooden veneer, check if there is too much grease on the back of the veneer or if the non-woven fabric (paper) on the back is too wet; Spray paint peeling off the wooden veneer, check whether the pores of the veneer are too large, and whether the solvent of the paint penetrates into the adhesive and damages the adhesive film; The quality of hot melt adhesive does not meet the requirements, and low-temperature adhesive is not suitable for use in such processes; Poor handling during edge sealing results in thick adhesive lines, leading to poor sealing and solvent penetration into the adhesive film, which can damage its strength.